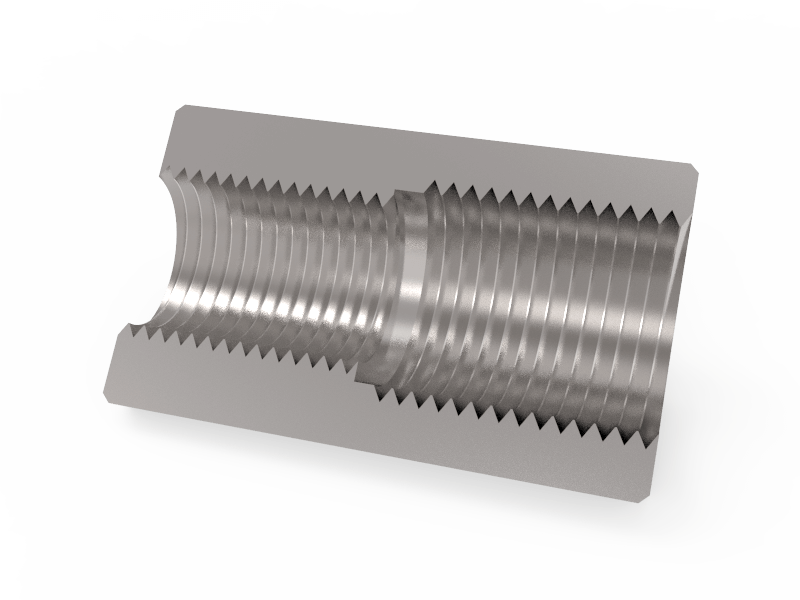

Itekcon’s engineered cold rolling process delivers threads that are stronger and smoother than cut threads. Cold Roll Technology strengthens the root and flank of the rebar threads and provides for a significant increased rebar/coupler connection. Cold rolling is the preferred method for forming threads and delivers superior tensile strength, shear strength, resistance to fatigue, and thread accuracy.

It includes Parallel thread rebar coupler, Taper thread rebar coupler, and Transition thread rebar coupler. It’s a more efficient splicing system, the need for that is becoming more apparent as a result of the increased construction complexities and design requirements.

This kind of rebar couplers can simplify the design and construction of reinforced concrete and reduce the amount of reinforcement required. It used anywhere the rebar need to extended in construction of reinforced concrete. Includes connections between rebars of the same diameter and of different diameters. Efficient replacement for hooked bars.

Features:

- Detection visualization: No need to check the internal condition of the joint, Proper installation ensures secure connections

- Save space: Using rebar couplers can avoid the congestion of rebars with lapped joints, keep the integrity of the structure. Decrease the size of concrete sections, then floor spaces are maximized

- Keep performance stable; Degradation of concrete can’t affect the performance of the rebar coupler.

- Low Cost; Material and cost savings as a result of useless steel.

- Easy to work: Easy installation, standard, and position, to avoid confusion and reduce, warehousing on site. Shortens construction cycle times.

Multiple Thread Rebar Coupler For Your Choose

Thread rebar coupler Tensile strength test

Rebar coupler test thread

Rebar coupler install